The concept of drones first appeared in 1849 in the form of unmanned balloons stuffed with explosives used by the Austrian forces to besiege Venice (Vyas, 2020). Since then, drones have grown in popularity. Over the last two decades, they are now used for everything from children’s toys and photography to even delivering goods; their functionality is almost endless. Drones have recently been accepted as a tool within the mining industry as an option for cheaper and safer exploration, mapping and monitoring of deposits, sites, and environmental values. They come with additional benefits, such as costing less than some traditional methods and having higher mobility (Mining Global, 2020).

But did you know that drones are not the only technology being used within the mining industry? Autonomous and Unmanned Remote Operational Vehicles (ROVs) also provide a wide range of uses. What are they, I hear you ask? Come with me as I run through some exceptional ROV technologies being utilised and developed within Australia’s mining industry and how you can utilise them for environmental monitoring.

Remote Operation Technologies

Unmanned Aerial Vehicles (Drones)

Drones have now been used on mine sites for many years. With the right photogrammetric cameras and software, they can produce highly accurate measurements by collecting georeferenced imagery. The imagery can then be utilised for numerous activities, including calculating volumes, heights, densities and other dimensions.

Analysis using these factors and additional data you have collected can help design site layouts, monitor stockpile levels, manage tailing dams, environmental monitoring, and be used in emergency response scenarios.

Autonomous Surface Vehicle

In 2018 bathymetric surveying was undertaken at a Norton Gold Fields Operation in Kalgoorlie (Xylem, 2018). Pit lakes were surveyed with ease from the comfort of the pit’s edge to complete a task that previously was labour and time-intensive.

Some mine pits are known to have pH levels as low as 1, giving the advantage to unmanned vehicle sampling for not only accuracy and time efficiency but also safety. The data is then used to provide accurate reporting for compliance, audits and research projects.

Remote Underwater Vehicles

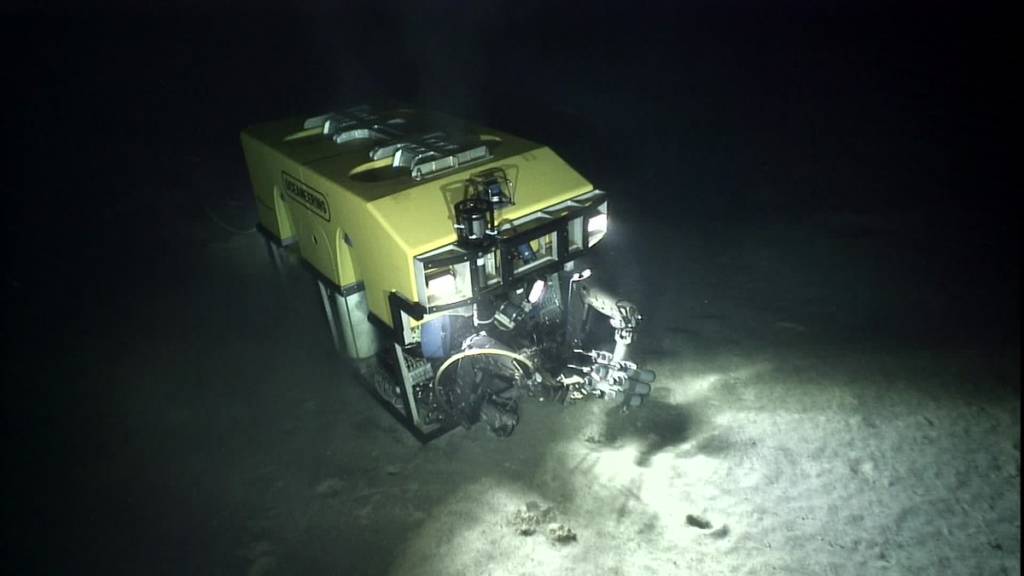

Underwater ROVs have been used in the oil and gas industry on marine structures for many years. They come in different shapes and sizes; each being utilised for the tasks at hand. Some of these tasks include pipeline inspections, equipment maintenance and environmental monitoring.

This technology is being developed worldwide to add autonomous underwater monitoring in the mining industry, including, but is not limited to monitoring TSF’s and flooded mining voids. The testing capabilities of these mini-subs include water quality testing, bathymetry, imagery and mapping (Smith, 2020).

These underwater vehicles can be used to take samples, monitor stratification and carry out inspection and maintenance of underwater infrastructure.

Remote High Risk / Emergency Response Vehicles

Much like the bomb squad robot, remote technologies have been utilised within Western Australia Mine Sites to combat high-risk emergency scenarios that would otherwise risk the life of workers.

In an underground mine in central Western Australia, a pressurised water pipe caused an emergency that required the evacuation of the mine due to unsafe conditions. The pressure in the pipe needed to be released. However, it was unable to be rectified by man. Thus ROVs were brought in by Woodside and Deakin University, with the assistance of the University of Texas and NASA (AROSE, 2019).

Risk assessments, machine coding and additional technology were tailored onsite for the specific needs of the task. ‘Ripley’ the robot entered the mine, controlled remotely from outside the tunnel, and successfully cut the pipe and released the water pressure battering the robot with water. With the site safe once more Ripley was recovered by his teammates.

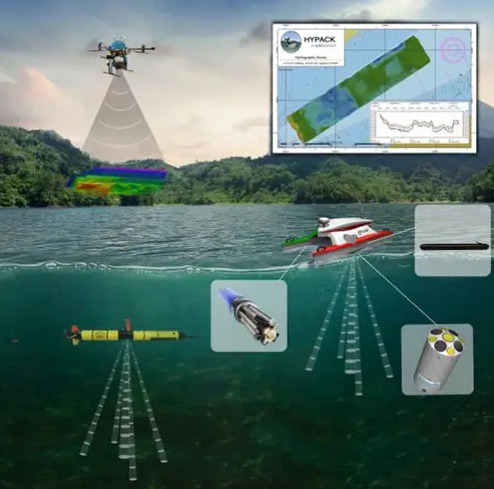

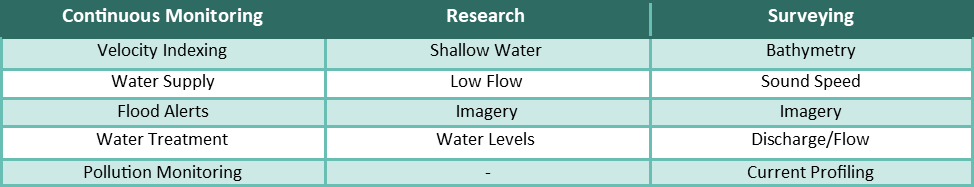

Applications for Mining

Autonomous vehicles can be sourced, designed, and built specifically to the job you need. With continuing advancements in technology, the potential for remote operation vehicles for mining activities are nearly limitless. Some examples of built to order remote operational vehicles can include the following technology (SonTek, 2018):

Technological advancements, when embraced, enable the worker to work smarter, not harder, during field studies, improve the accuracy of monitoring and research activities, provide timely and safe approaches that can also be more cost-effective.

Are you and your company ready to take the leap into the future and lead the industry through using autonomous and remote vehicles to do the hard yards?

If you are interested in these or any other technological advancements that could aid your business, contact Integrate Sustainability on 9468 0338 or enquires@integratesustainability.com.au to see how we can help you.

References

AROSE. (2019). Robotics in Underground Mine site. Retrieved from AROSE: https://www.arose.org.au/#projects

Mining Global. (2020, May). The Mining Sector Puts Drones to Work. Retrieved from Mining Global: https://miningglobal.com/technology/mining-sector-puts-drones-work

Smith, S. (2020, March). Water Monitoring Quality with Vehicles for Better Coverage. Retrieved from YSI: https://www.ysi.com/ysi-blog/water-blogged-blog/2020/03/water-quality-monitoring-with-vehicles-for-better-coverage

SonTek. (2018). Instrument Selection Guide. Retrieved from SonTek: https://www.sontek.com/products

Vyas, K. (2020, June). A Brief History of Drones: The Remote Controlled Unmanned Aerial Vehicles (UVAs). Retrieved from Interesting Engineering: https://interestingengineering.com/a-brief-history-of-drones-the-remote-controlled-unmanned-aerial-vehicles-uavs

Xylem. (2018, April). Remote Bathymetric Survey in Kalgoorlie Mine Pits, Australia. Western Australia: Xylem.