In recent years, the urgency of addressing climate change has highlighted the need for innovative solutions to reduce carbon emissions, with global temperatures predicted to increase by 1.5 degrees Celsius by 2050 (WMO, 2023). The mining industry in Australia is a significant contributor to greenhouse gas (GHG), increasing 115.6% since 1990 (DCCEEW, 2022), and is estimated to be responsible for 4 to 7 % of global greenhouse emissions (Global Data, 2022).

The potential of carbon storage via mineral carbonation (also known as carbon mineralisation) in mine waste and tailings is a compelling avenue for carbon mitigation, with 7 billion tonnes of mine tailings generated annually worldwide (Araujo, et al., 2022). Tailings are produced as a by-product of mineral processing activities and often contain elements that have the potential to react with carbon dioxide to form a new material. Harnessing this potential could lead to removing carbon dioxide from the atmosphere while repurposing otherwise unused material.

This insight introduces the concepts of carbon storage through mineral carbonation and its potential to assist with reducing GHG emissions.

What is Carbon Storage:

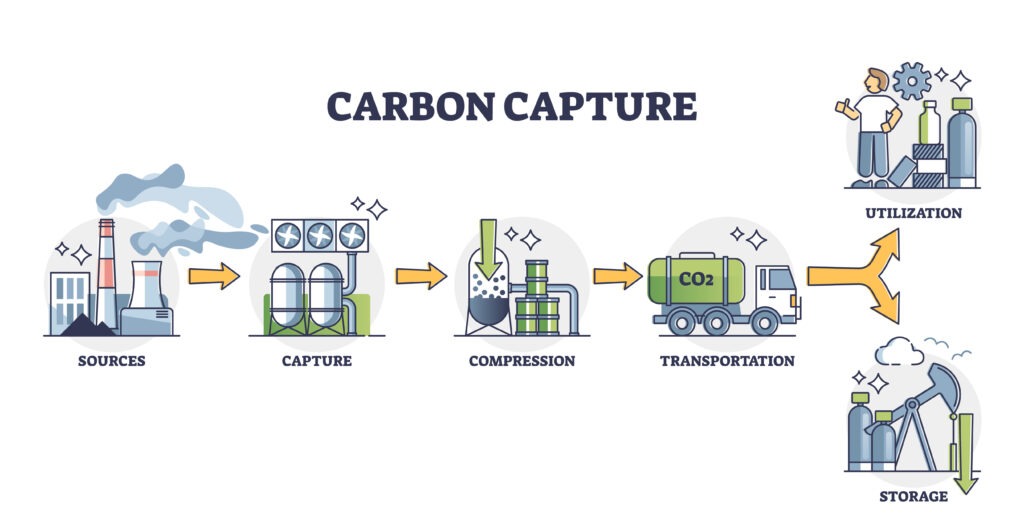

Carbon storage, otherwise known as carbon capture, is a process of trapping carbon dioxide (CO₂) taken from the atmosphere from an industrial source point, transporting it, and processing it for use or storage (Figure 1) (Geoscience Australia, 2022). This process is called Carbon Capture, Use and Storage (CCUS), in which industries can reuse the carbon captured within an industrial setting, or Carbon Capture and Storage (CCS), where the carbon is captured and stored.

Within mining, geological storage can be used to store carbon on-site through mineral carbonation.

What is Mineral Carbonation:

Natural rock weathering occurs when carbon dioxide is captured from the atmosphere and reacts with certain minerals within rock formations to produce a new solid mineral called carbonates, which can permanently store carbon dioxide.

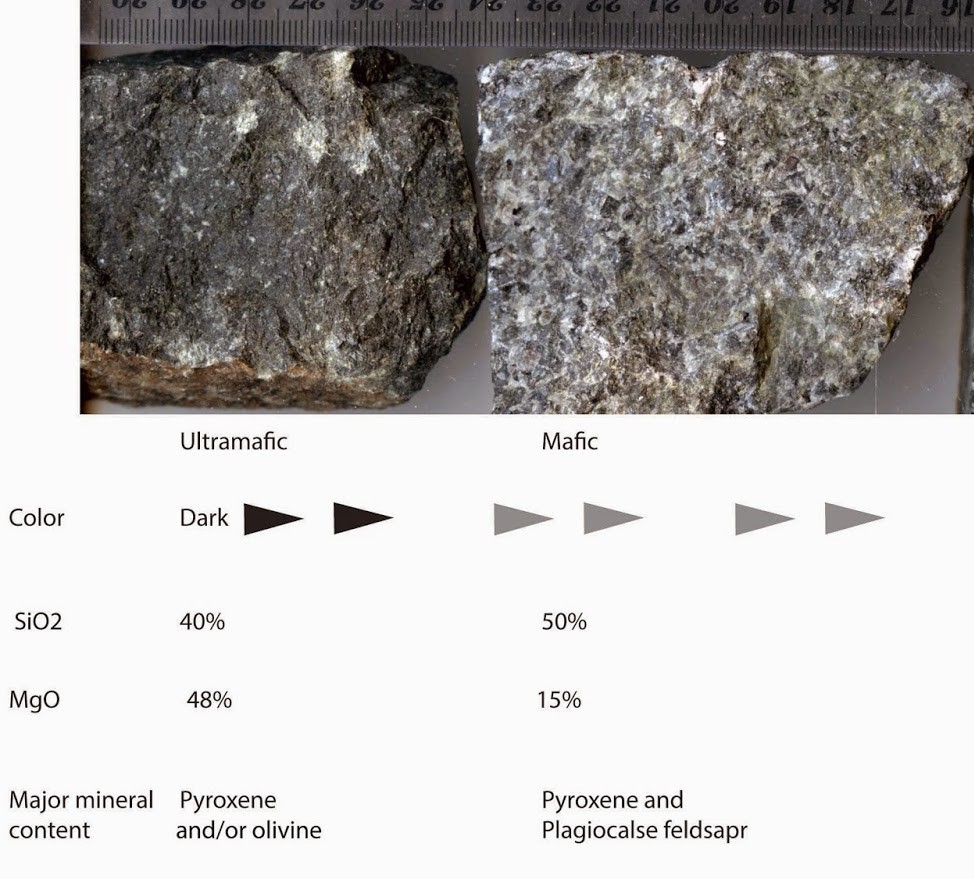

This reaction requires alkaline rocks with specific mineral properties, which are highly reactive to CO₂. These rocks typically are mafic (high silica and lower magnesium) or ultra mafic rocks (high magnesium and lower silica) (Figure 2). They contain magnesium oxide or calcium oxide-bearing silicates. Ultramafic rocks are the better choice for mineral carbonation due to their higher magnesium component (Riedl, et al., 2023).

The following reaction explains the mineral carbonation process (Molahid, et al., 2022):

Metal Oxide + CO2 → Metal Carbonate + Heat

The most significant advantage of mineral carbonation is that the carbon cannot escape into the atmosphere afterwards, resulting in a permanent solution to carbon storage (CSIRO, 2023).

Two processes of Mineral Carbonation can occur:

In-situ – Refers to the process of mineral carbonation underground where CO₂ is injected into geological formations containing magnesium or calcium. The result is a natural mineral carbonation process over an extended period (CSIRO, 2022a).

Ex-situ – Refers to the processes at the earth’s surface (CSIRO, 2022a). Rock is removed from underground and brought to the surface where it can react with the CO₂ in the atmosphere. As a result, ex-situ processes enable the development of technologies to accelerate the natural processes that may already occur in mine tailings or mining waste.

Mineral Carbonation within Mining:

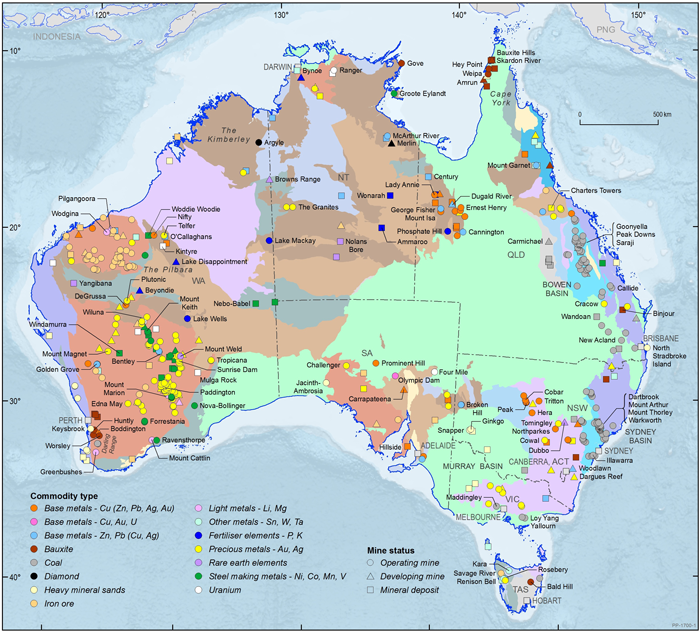

Australia has an abundance of different mines (Figure 3), each with different geology and mineral availabilities. For mineral carbonation to succeed, there must be an abundance of magnesium (Mg) in mining residues. Some rock formations such as Serpentine, Olivine, Orthopyroxene, Clinopyroxene and Amphibole have a high content of Mg, making them good candidates.

Mineral carbonation is one option mining could consider to lock up CO₂ through CCUS. Ultra-mafic mine waste, such as waste rock and processing (tailings) waste, acts as a feedstock for the process. The advantage of using feedstocks like mine tailings is that grinding is not required, as it already has a higher surface area, providing a greater surface area for the reaction.

Mineral Carbonation Methods:

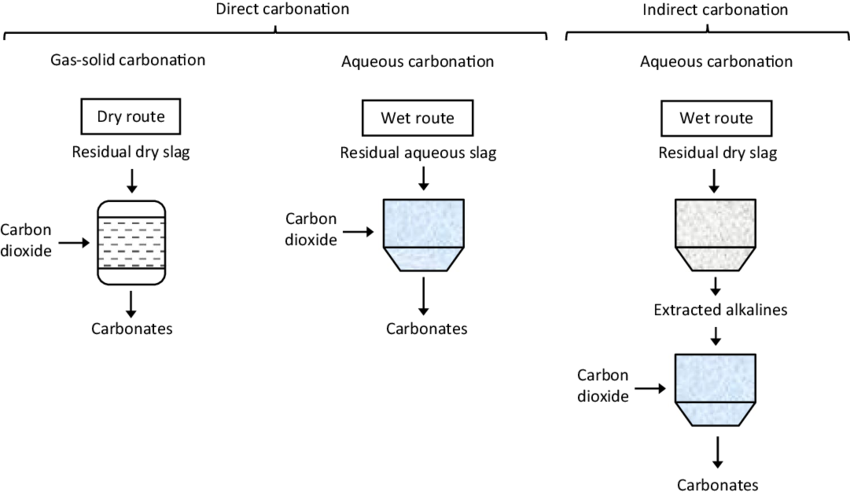

Two methods can achieve mineral carbonation: Direct or Indirect (Figure 4) (Baena-Merona, et al., 2022). Direct mineral carbonation is a one-step method, and indirect carbonation is a multiple-step method. Direct mineral carbonation may occur via a gas-solid or aqueous process. Gas-solid carbonisation is where CO₂ is injected directly into the feedstock. Aqueous carbonation entails adding a water solution to achieve carbonation through dissolution and precipitation (Stokreef, et al., 2022). Indirect carbonation is where the divalent minerals are extracted and processed in such a way as to change their properties, which then react with the CO₂.

Could your mine waste be suitable for CO₂ storage?

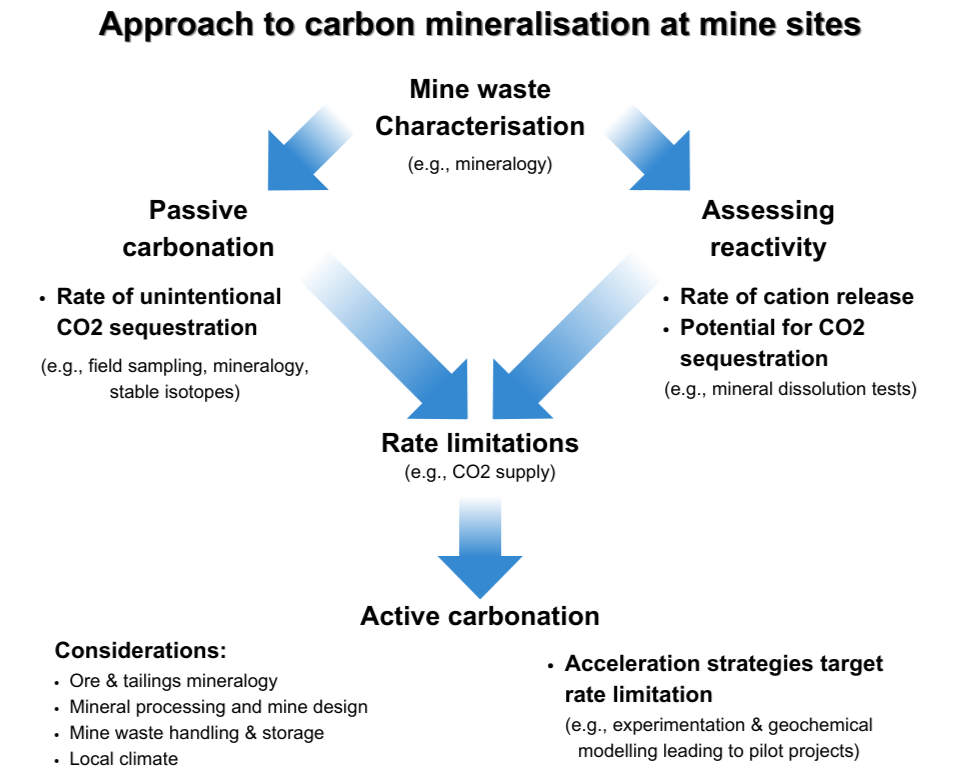

Mineral carbonation requires multiple steps (Figure 5) (CSIRO, 2023). The first step is to identify whether the mine has the potential for mineral carbonation because it is associated with the correct rock types (e.g., mafic or ultra-mafic). This information will be available via the mine geological database. Once the correct geology has been identified, steps can be taken to assess other factors associated with mineral carbonation. These include laboratory assessments, determining possible carbonation strategy, storage options, handling and transport.

Australia’s Roadmap for Mineral Carbonation

CSIRO is producing a roadmap for Australia for Carbon Capture and Utilisation (CCU). This roadmap explores how Australia can upscale their use of CCU and identifies its future opportunities for the use of CO₂ (CSIRO, 2022b). This research will provide further insight into which rocks and minerals have the greatest mineral carbonation potential, identifying the most effective process, developing modelling for processes and assessing the risks involved in achieving mineral carbonation (CSIRO, 2023).

Within Western Australia, Curtin University’s School of Mines, in collaboration with the Minerals Research Institute and BHP, are currently leading the way in developing a State Government roadmap for integrated mineral carbonation (Curtin University, 2022).

Source: (Mervine, et al., 2018)

Challenges of carbon storage via mineral carbonation in mining.

The use of mineral carbonation in mining is in its infancy, with technologies that help accelerate the mineral carbonation processes being trailed but not yet commercially available (Kalbani, et al., 2023; Kelemen, et al., 2019).

Also of note is that the legislation associated with this activity is still being developed. In February 2023, the WA government released a draft Bill (The Petroleum Legislation Amendment Bill (B) 2023) (DMIRS, 2023) for Western Australia’s road to Net Zero, designed to have new greenhouse storage and transport provisions. The new bill seeks to introduce legislation for greenhouse gas capture similar to the Commonwealth’s Offshore Petroleum and Greenhouse Storages Act 2006.

Why should mining companies still consider carbon storage via mineral carbonation?

There is value in considering mineral carbonation; some of these include:

· CCUS is a crucial feature of Australia’s technology investment roadmap to reduce emissions, and specific funding is currently being allocated towards research and development (Kalbani, et al., 2023).

· Ex-situ mineral carbonation in Australia presents an economic advantage, with many mines already producing the materials needed.

· Legislation changes are ongoing to outline the greenhouse gas emissions targets, provision and storage. Understanding these legal changes is essential to ensure businesses comply with Australia’s national and state laws.

· Assessment of each mine’s geological data can prepare you for the next steps in anticipation of the new technologies and methods being released.

· Getting ahead within individual mines will allow mines to be a part of an increasingly growing industrial practice.

· The future of mineral carbonation could include Carbon Credits (Carbon Credits, 2022), a system designed to incentivize companies to reduce their carbon emissions. This framework will open doors to attract more market investors and boost CCUS research.

Integrate Sustainability Pty Ltd is striving to stay updated on the new research, laws and technologies within the area of mineral carbonation and the future developments of CCUS. If your company wants to explore potential site eligibility and options for mineral carbonation, call us on 08 9468 0338 or email us at enquiries@integratesustainability.com.au.

References

Araujo, F. S., Taborda-Llana, I., Nunes, E. B. & Santos, R. M., 2022. Recycling and Reuse of Mine Tailings: A Review of Advancements and Their Implications. [Online]

Available at: https://doi.org/10.3390/geosciences12090319

Baena-Merona, F. M. et al., 2022. Effluents and residues from industrial sites for carbon dioxide capture: a review. [Online]

Available at: https://doi.org/10.1007/s10311-022-01513-x

BE&R, 2022. Carbon Capture and Storage (CCS) – Energy Hurdles. [Online]

Available at: https://berconsulting.com.au/2022/10/14/carbon-capture-and-storage-energy-hurdles/

Carbon Credits, 2022. Generating Carbon Credits from Mining Waste. [Online]

Available at: https://carboncredits.com/bhp-carbon-mineralization/#:~:text=But%20if%20BHP%20is%20successful,million%20carbon%20credits%20each%20year.

[Accessed 29 08 2023].

CSIRO, 2022a. Australia’s carbon sequestralia potential: A stocktake and analysis of sequestration technologies. [Online]

Available at: https://www.csiro.au/-/media/Missions/TNZ/CCA-report/CCA-Report-Australias-Potential-Sequestration-Final-28-November-2022.pdf

CSIRO, 2022b. CO2 Utilisation Roadmap. [Online]

Available at: https://www.csiro.au/en/work-with-us/services/consultancy-strategic-advice-services/csiro-futures/energy-and-resources/co2-utilisation-roadmap

CSIRO, 2023. Carbon Mineralisation. [Online]

Available at: https://research.csiro.au/carbonlock/research/work-packages/carbon-mineralisation/

[Accessed 21 08 2023].

Curtin University, 2022. Curtin leads the way in mineral carbonation for a greener future. [Online]

Available at: https://www.curtin.edu.au/news/media-release/curtin-leads-the-way-in-mineral-carbonation-for-a-greener-future/

DCCEEW, 2022. National inventory by economic sector: annual emissions. [Online]

Available at: https://www.dcceew.gov.au/climate-change/publications/national-greenhouse-accounts-2019/national-inventory-by-economic-sector-annual-emissions

DMIRS, 2023. Draft Bill helps build foundations to decarbonisation. [Online]

Available at: https://www.dmp.wa.gov.au/News/Draft-Bill-helps-build-30820.aspx

Geologyin, 2023. How to Classify Igneous Rocks Into (Ultramafic, Mafic, Intermediate and Felsic)?. [Online]

Available at: https://www.geologyin.com/2014/12/how-to-classify-igneous-rocks-into.html

Geoscience Australia, 2018. Australia leading the world in the latest mineral resource statistics. [Online]

Available at: https://www.ga.gov.au/news-events/news/latest-news/australia-leading-the-world-in-the-latest-mineral-resource-statistics

Geoscience Australia, 2022. What is CCS? [Online]

Available at: https://www.ga.gov.au/scientific-topics/energy/resources/carbon-capture-and-storage-ccs/what-is-ccs

Global Data, 2022. Total GHG Emissions of Major Metals and Mining Companies Worldwide by Revenue in 2021. [Online]

Available at: https://www.globaldata.com/data-insights/mining/total-ghg-emissions-of-major-metals-and-mining-companies-worldwide-by-revenue-2090961/#:~:text=%2456%2C921%20million%20respectively-,Total%20GHG%20Emissions%20of%20Major%20Metals%20and%20Mining,by%20Revenue%

Kalbani, M. A., Serati, M., Hofmann, H. & Bore, T., 2023. A comprehensive review of enhanced in-situ CO2 mineralisation in Australia and New Zealand. [Online]

Available at: https://www.sciencedirect.com/science/article/pii/S0166516223001349

Kelemen, P. et al., 2019. An Overview of the Status and Challenges of CO2 Storage in Minerals and Geological Formations. [Online]

Available at: https://www.frontiersin.org/articles/10.3389/fclim.2019.00009/full

Mervine, E. et al., 2018. Potential for offsetting diamond mine carbon emissions through mineral carbonation of processed kimberlite : an assessment of DeBeersmine sites in South Africa and Canada. [Online]

Available at: https://doi.org/10.1007/s00710-018-0589-4

Molahid, V. L. M. et al., 2022. CO2 Sequestration through Mineral Carbonation: Effect of Different Parameters on Carbonation of Fe-Rich Mine Waste Materials. [Online]

Available at: https://doi.org/10.3390/pr10020432

Riedl, D. et al., 2023. 5 Things to Know About Carbon Mineralization As a Carbon Removal Strategy. [Online]

Available at: https://www.wri.org/insights/carbon-mineralization-carbon-removal#:~:text=Carbon%20mineralization%20is%20a%20process,securely%20remove%20and%20sequester%20CO2.

Stokreef, S., Sadri, F., Stokreef, A. & Ghahreman, A., 2022. Mineral carbonation of ultramafic tailings: A review of reaction mechanisms and kinetics, industry case studies, and modelling. [Online]

Available at: https://doi.org/10.1016/j.clet.2022.100491

WMO, 2023. Global temperatures set to reach new records in next five years. [Online]

Available at: https://public.wmo.int/en/media/press-release/global-temperatures-set-reach-new-records-next-five-years