Since the industrial revolution, there has been a demand for plastic products and packaging across the world. This is mainly due to the properties of plastics because they are easy to transport, extremely durable, can be resistant to chemical products and act as thermal and electrical insulators. Plastic is also a cheaper product than other alternative materials making it a financial decision for many companies. However, due to the durability of plastics, there is an accumulation of plastics waste, creating management problems, pollution and environmental damage. More recently, there has been increased interest in the recyclability and re-use of plastic products due to environmental concerns by governments and consumers worldwide.

Types of Plastics and their Recycling

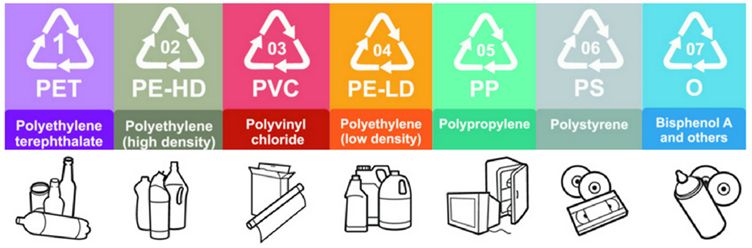

There are seven types of plastics, each with different recycling codes. These are:

- Polyethylene Terephthalate (PET or PETE): commonly found in bottles and food containers. These plastics are easily recyclable and accepted through most recycling schemes.

- High-Density Polyethylene (HDPE): The most common plastic globally is solid and resistant to moisture and chemicals, making it ideal for cartons, containers, pipes, etc. This is one of the newest plastics, most recycled plastic and is usually deemed safe for food containers.

- Polyvinyl Chloride (PVC or Vinyl): is one of the oldest plastics that starts out rigid but becomes flexible. PVC does not conduct electricity making it familiar for high-tech applications. This is seldom recycled.

- Low-Density Polyethylene (LDPE): A softer, clearer, and more flexible version of HDPE, the LDPE is easiest to produce but still quite difficult to recycle. It can be found as plastic/cling wrap, sandwich and bread bags, bubble wrap, and garbage bags and recycled through a RedCycle program.

- Polypropylene (PP): This is one of the most durable types of plastic. It is more heat resistant than some others, making it ideal for food packaging. Polypropylene plastic can be recycled. However, it often isn’t.

- Polystyrene (PS or Styrofoam): Cheap and easy to create, Polystyrene have been extensively used and throw-away, although some recycling programs may accept it. Like PVC, Polystyrene is considered to be a dangerous plastic. It can easily leach harmful toxins such as styrene (a neurotoxin), which can easily be absorbed by food and thus be ingested by humans.

- Other: Plastics other than the ones outlined above.

The global recycled plastics market is dominated by four major plastics: PET, HDPE, Polypropylene, and LDPE. The largest of these segments is PET making up approximately 55% of the total recycled plastic.

Environmental issues associated with incorrect disposal have made plastic materials the target of significant public pressure, which has boosted their recycling. The plastic recycling sector was structured and is today a very representative economic activity, with strong demand for technology, products and specialised services (Schandl H, 2020). This has seen an increase in recycled plastics to create or replace products used in many sectors.

Use of Recycled Plastics in Different Sectors

One of the solutions to the global plastic problem is using recycled plastic to make new products reducing the consumption of other raw materials while also reducing plastic from going to landfills. Recycled plastics are now being used in many different industries and are continuing to be developed.

Civil Construction

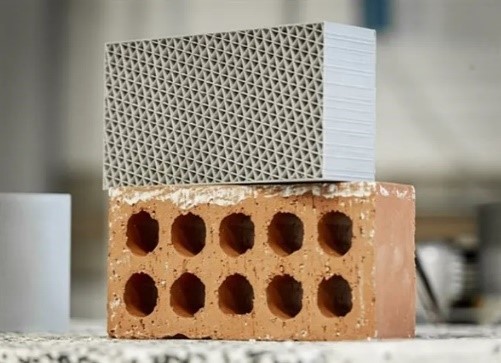

The civil construction industry is one of the main sectors that has been increasing the use of recycled plastic products. One such product is plastic bricks (Figure 1). The recycling process transforms plastic from landfills into various materials used in architectural projects for homes. To build an 80m² house from plastic bricks will recycle around 2,500kg of plastic.

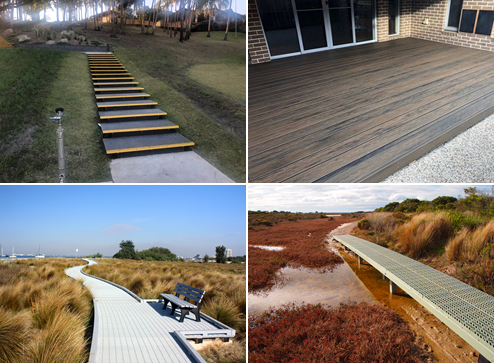

Other products made from recycled plastic are also being used globally in civil construction, such as decks, bridges, walkways, and stairs (Figure 2). This recycling and development process can allow the recycled plastic to take on shapes and colours that make it look very similar to wood, cement or steel, contributing to design elements and providing longevity of these materials.

Furniture

One of the most significant designs companies, Antwerp-based brand Ecobirdy, has launched children’s furniture made entirely from recycled plastic. This process starts with the collection of plastic children’s toys which then go through sorting and cleaning. The plastic material is ground which generates the plastic flakes used in production. These are then moulded to create furniture such as the chairs (Figure 3).

Recycled plastic is also being used to make outdoor furniture, specifically for use in outdoor recreational areas. The plastic is virtually maintenance-free and can be found in a range of widths, lengths and colour options. The benefits of using recycled plastic for outdoor furniture include a high UV resistance, ensuring the longevity of the pieces. Outdoor furniture installation is simple as the furniture comes flat packed and is easy to assemble. In Figure 4, there are some examples of recycled plastic in public spaces.

Fashion

Recycled plastics are also being used to create clothing and footwear products, with many brands beginning to invest in the sustainability of their products.

Some of the largest clothing and footwear companies are also operating several changes in their production lines and have an essential role in increasing the volume of recycled plastic in their production, particularly synthetic fibres and materials. One of the biggest campaigns has been “MOVE TO ZERO” which was launched by Nike. In addition to establishing several internal changes to avoid waste, Nike also invests in several product lines made with recycled plastic, such as shoes (Figure 6).

Products and fabrics made from recycled plastics like those outlined above are a great idea. However, the long-term disposal strategies and breakdown for such products still need to be realised.

Australia’s Plan for Plastics

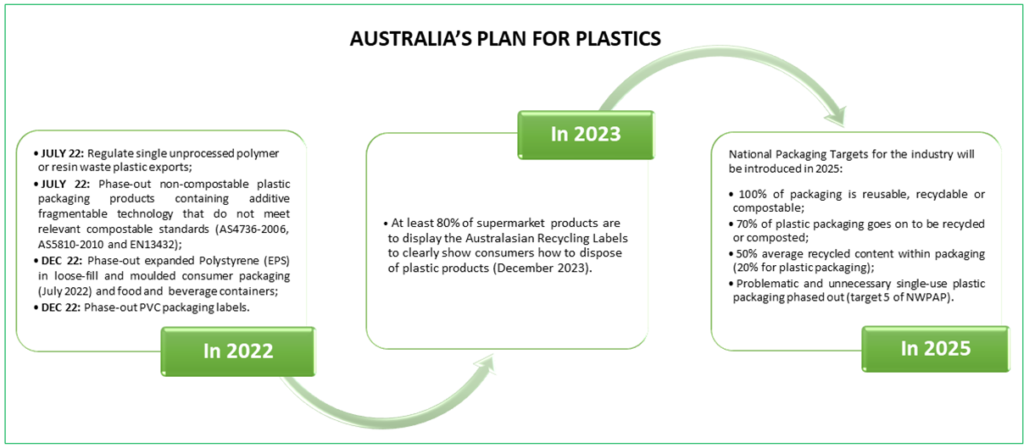

In response to community consultation to reduce the impacts of single-use plastics, find alternatives to unnecessary plastics and reduce the impact of plastic on the environment, the Australian Government has launched the “National Plastics Plan 2021” which shows the goal and steps to reduce the plastic impacts in Australia. The Plan explains how Australia intends to deal with plastic in the coming years and how these changes in the national plastic market will influence the reduction or replacement of plastic (Department of Agriculture, 2021). For example:

The full Plan is available online and you can access it through this link – National Plastics Plan.

All of the plastic ever produced is still around today. Businesses and governments must unite to use technology to combat plastic consumption, even with plastic recycling and innovative ways to re-use plastic in everyday products. The long-term management implications from the durability of plastic products will still be of concern in years to come, particularly as we try to determine how plastic and recycled plastic products can be safely disposed of. The best way to manage plastics is to phase out the use of plastic products.

If you or your organisation would like to learn more about recycling plastics or removing single-use plastic from your company, please contact us by email at enquiries@integratesustainability.com.au or call us on 08 9468 0338.

References

(APRA), The Alberta Plastics Recycling Association. 2021. The Alberta Plastics Recycling Association (APRA). Accessed 07 20, 2021. https://albertaplasticsrecycling.com/resources-education/plastics-recycling-in-four-simple-steps/.

Australia, Southern Territory. 2021. “Container Deposit Legislation – Southern Territory Australia.” 07 20. Accessed 07 20, 2021. https:// www.revolvy.com/page/Container-deposit-legislation-in-Australia.

Conroy, Gemma. 2121. ABC Science Biodegradable plastic that can break down in your compost developed by scientists. April 21. Accessed 07 25, 2021. https://www.abc.net.au/news/science/2021-04-22/biodegradable-plastic-compost-enzymes-environment-soil-green/100082958.

Department of Agriculture, Water and the Environment. 2021. “DAWE 2021, National Plastics Plan 2021.” Canberra, December. CC BY 4.0.

District, Material. 2018. Material District. April 12. Accessed 07 20, 2021. https://materialdistrict.com/article/childrens-furniture-recycled-plastic-toys/childrens-furniture-made-from-recycled-plastic-toys-4.

Locock, KES. 2017. The Recycled Plastics Market: Global Analysis and Trends. Australia.: CSIRO.

Schandl H, King S, Walton A, Kaksonen AH, Tapsuwan S and Baynes TM. 2020. National circular economy roadmap for plastics, glass, paper and tyres. Australia. ISBN 978-1-4863-1495-9: CSIRO.