If you have ever tried to build anything out of blocks, you will be familiar with that heart-wrenching moment when it all comes crashing down as a result of the wind, the toddler or pet. From the onset, the chance of the tower surviving is minimal, despite the limited number of external pressures. Now compare the construction of this tower to that of some of our mining creations – say a waste rock landform, pit or tailings facility, some of which are expected to stand the test of time. These structures are subject to a range of pressures which determine their stability and/or the safety for people and the environment.

Materials in Material Characterisation, refer to all soils, subsurface and non-economic materials that have been disturbed or extracted during resource extract activities and includes material that has been physically or chemically processed on-site. Material characterisation seeks to identify the physical and geochemical properties of materials and classifies them as to whether they have the potential to cause environmental harm, or contribute to or impact on the success of rehabilitation and closure activities (DMIRS, 2016).

Material characterisation is an important part of the design and construction phase of a mining project to ensure your landform does not come crumbling down like our block tower. This insight looks at the importance of characterising mines waste streams in terms of their physical and chemical properties and the value of identifying the potential for environmental harm.

Mine Wastes

Mine wastes are solid, semi-solid, liquid or gaseous by-products of mining, mineral processing, and metallurgical extraction that have no current economic value and accumulate at a mine site. Volumetrically, mine waste accounts for one of the world’s largest waste streams and often contain high concentrations of elements and compounds that can have severe effects on human health and our ecosystems (Hudson-Edwards, Jamieson, & Lottermoser, 2011). As a result, it is important to accurately identify the properties of wastes to ensure appropriate management.

Many different types of waste streams are generated throughout the mining and processing of ore include mine overburden/waste rock, uneconomic material/mineralised waste, tailings, slags, ashes and waste water (Kuranchie, Shukla, & Habibi, 2016). Waste rock and tailings characterisation are of particular importance as they often end up as part of constructed landforms that could be adversely affected by the properties of the waste material. Overburden or waste rock is material removed from the ground in order to access the desired ore, while tailings are generated during the processing phase (Department of Industry, Innovation and Science, 2016). Tailings are crushed rock and processing fluids from a mill, washery or concentrator resulting from the removal of the economic metals, minerals, mineral fuels or coal from the mined resource. It is not uncommon for the waste generated during the crushing and processing activities to be referred to as processing waste.

In order to successfully manage mine wastes a number of things need to be considered such as the physical and chemical characteristics of the waste, and any potential hazards to people and the environment the waste might create (Vivoda & Fulcher, 2017). The type of waste, the characteristics of the waste and the intended end use of the waste will determine whether a potential hazard exists. While the characterisation of waste is applicable from a hazard perception, it is important the physical and chemical properties of rehabilitation materials are also assessed.

For the purpose of this InSight, material characterisation has been separated in physical and chemical properties.

Physical Properties

Physical properties of a material can impact on the structure and stability of the landform. Physical properties can either cause or mitigate dispersion, erosion and stability, as well as influence water repellence and infiltration. The typical analysis used to assess the physical properties of the material includes:

- Bulk Density – used to determine the weight of soil in a given volume thereby commenting on the compactness of soil.

- Particle Size Distribution – defines the proportion of sands, silts and clays within the soil medium. Particle size distribution informs the assessment of erosion and sodicity risks.

- Aggregate Stability – used to determine the stability of the soil when immersed in water. Instability may be indicated by slaking or dispersion

- Water Repellence – determines how susceptible the soil is to water, sandy soils can be susceptible to waxy organic compounds preventing wetting and impacting rehabilitation efforts.

The causes of erosion can often be attributed to physical properties such as particle size, texture and bond strength. For example, finer grained sandy soils are more susceptible to wind erosion than clays (generally), whereas material with low infiltration rates and weak bonds are more susceptible to water erosion (DMIRS, 2016)

Chemical Properties

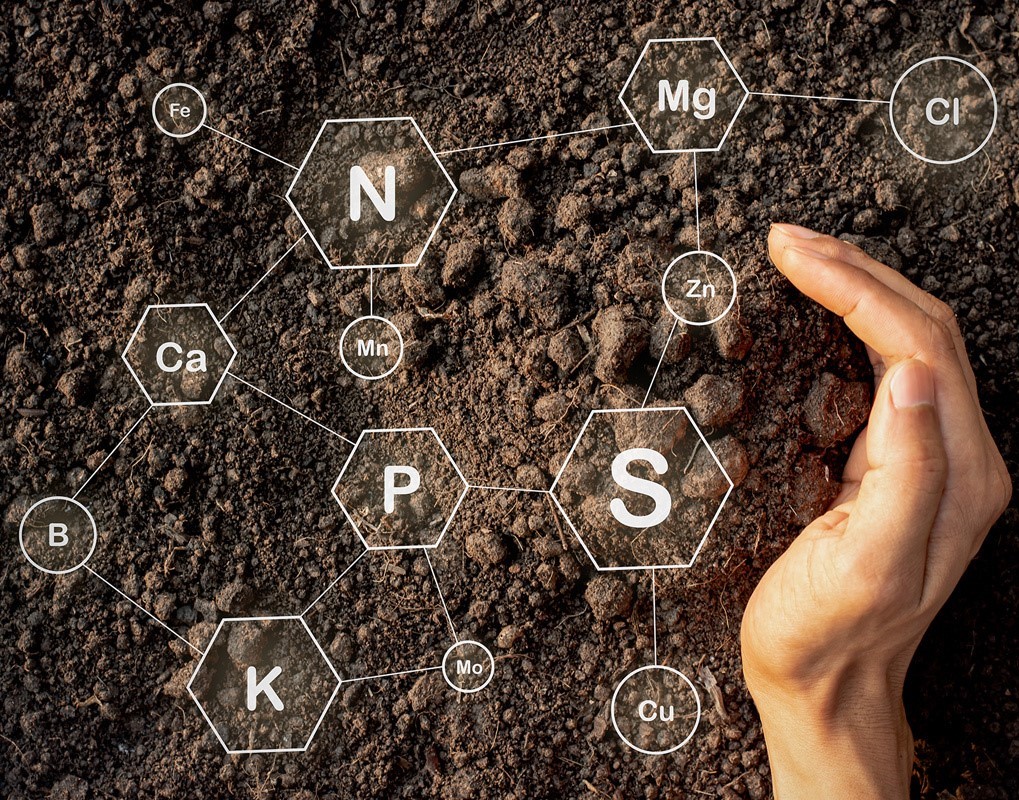

The chemical properties of the material can be attributed to a number of factors such as the geology or the environment the material occurs in. Chemical properties if incorrectly managed, can lead to environmental impacts such as acidic and/or metalliferous drainage (AMD), salinity, erosion and dispersion. Poor chemical (and physical) properties can also impact rehabilitation success. Some useful analysis to help determine the characteristics of materials are (DMIRS, 2016):

• pH – characterises the chemical environment of the soil. The soil’s pH affects the availability of various nutrients, toxic elements and chemicals.

• Electrical conductivity/Total Dissolved Solids – used as measure of salinity and therefore provides information on suitability on the soil as a growth medium and dispersion potential.

• Exchangeable Cations – a measure of the soil’s capacity to hold important cations. Cation composition of a soil can determine how sodic it is and the likelihood of dispersion.

• Organic Carbon – an indicator of soil nutrient store (mainly relevant for topsoil).

• Available Nutrients (Phosphorous, Potassium and Sulphur) – a measure of the nutrients available for plant uptake (mainly relevant for topsoil).

• Metals – determines the concentrations of metals in the material and hence provides information on which metals may be leached.

• Leaching – can be conducted at a variety of pH levels but ultimately determines the likelihood of elements or compounds leaching from material and entering waterways, groundwater or contaminating other soils.

• Net Acid Generation (NAG), Net Acid Producing Potential (NAPP), Acid Neutralising Capacity (ANC) and Total Sulphur – results are used to determine whether the material is considered acid forming or non-acid forming and determines the requirement for additional testing.

This is by no means an extensive list of the analytical parameters that should be carried out when assessing waste materials, nor will all be applicable in every situation. Analytical parameters should be selected based on the outcome of geology and pre-screening review. The Draft Guidance on Material Characterisation published by DMIRS in 2016 contains an array of information, but it is always recommended that you consult with a suitably qualified professional.

Environmental Harm

Mining can create hazards for the environment that extend beyond changes to the physical landscape. One of these hazards is increased salinity. Soil salinity can have a major impact on rehabilitation efforts by inhibiting vegetation establishment and landform stability through increased risk of erosion. Material characterisation of rehabilitation resources is essential to ensure growth mediums such as topsoil are suitable for rehabilitation uses and to determine what additional controls may need to increase stability for landforms.

Acid generation from the oxidation of sulphide minerals, such as pyrite and pyrrhotite, in mine wastes, is one of the issues the mining industry must address (Hudson-Edwards & Dold, 2015; Harraz, 2010). The oxidation process leads to the production of acid at much higher rates than those that occur naturally due to the greater exposed surface area resulting from mining activities in comparison to that of undisturbed rock (Mineral Resources Tasmania, 2020; Department of Industry, Innovation and Science, 2016). This process is referred to as acidic and/or metalliferous drainage (AMD) and can have a major impact on the environment. AMD may be very acidic (low pH) and contain elevated concentrations of metals, metalloids and major ions and have low concentrations of dissolved oxygen. Hence, it can present a risk to aquatic life, stock, riparian vegetation and humans near or away from the mine ( Australian Government Department of Industry, Tourism and Resources, 2016). Material characterisation is vital to determine the appropriate management of mined wastes and preventing significant impact on the environment from AMD. For more information on AMD, visit Preventing Acid and Metalliferous Drainage.

Material characterisation is important throughout all stages of a mines life as it helps to assess, mitigate and control risks and may be required to appropriately respond to incidents. A key aspect of risk management is preparedness, and in order to be prepared, information and data are required. By knowing all the facts and making appropriate, reasonable and educated assumptions, risks such as those presented by salinity or AMD can be avoided through the implementation of management measure. For example, by understanding the properties of the material, sulphidic materials can be isolated or appropriately neutralised to mitigate or prevent AMD (INAP, 2009).

The team at Integrate Sustainability has a wealth of experience developing practical management plans and recommending cost-effective management measure to assist with the management of mine wastes and rehabilitation materials. If you have a new or existing project with mining or processing waste challengers. Please give us a call on (+618) 9468 0338, or contact us via email: enquiries@integratesustainability.com.au.

References

Australian Government Department of Industry, Tourism and Resources. (2016). Preventing Acid and Metalliferous Drainage: Leading Practice Sustainable Developemtn Program for the Mining Industry.

Department of Industry, Innovation and Science. (2016). Hazardous Materials Management: Cover image: Leading Practice Sustainable Development for the Mining Industry. Australian Government .

DMIRS. (2016). Draft Guidance Materials Characterisation Baseline Data Requirements for Mining Proposals. Department of Mines, Industry Regulation and Safety (formerly DMP).

Earth Systems. (2020). Waste Rock Management. Retrieved June 2020, from https://www.acidmetalliferousdrainage.com/waste-rock-management/

Harraz, H. (2010). Mine Wastes. Tanta University: ResearchGate.

Hudson-Edwards, K. A., Jamieson, H. E., & Lottermoser, B. G. (2011). Mine Wastes: Past, Present, Future. Elements, 7(6), 375-380.

Hudson-Edwards, K., & Dold, B. (2015). Mine Waste Characterization, Management and Remediation. Minerals, 5, 82 – 85.

INAP. (2009). Global Acid Rock Drainage Guide. The International Network fur Acid Prevention.

Kuranchie, F., Shukla, S., & Habibi, D. (2016). Study on Mine Wastes as Potential Resource for Brick Manufacturing in Western Australia. Western Australia: ResearchGate.

Mineral Resources Tasmania. (2020). Management of Acid and Metalliferous Drainage in Tasmania: Good Practice Guidance 2020-2025. Tasmania: Department of State Growth.

Roddy, B., & Howard, E. (2016). Hydrological function of berms within a waste landform design. Proceedings of the 11th International Conference on Mine Closure, Australian Centre for Geomechanics, Perth, 63 – 74.

Spitz, K., & Trudinger, J. (2008). Mining and the Environment: From Ore to Metal. CRC Press.

Vivoda, D., & Fulcher, D. (2017). Mine Waste Classification and Management (Series on International Best Practices, Working Paper No. 1, Mining Legislation Reform Initiative). Yerevan, Armenia: American University of Armenia; Center for Responsible Mining.